Architekturstudium an der Hochschule für angewandte Wissenschaften Coburg, Postgraduiertendiplom an der Städelschule in Frankfurt am Main 2002. Von 2003 bis 2006 lebte er in Amsterdam, Mitarbeit bei UN Studio / Van Berkel & Bos und Benthem Crouwel Architekten. 2006 Gastbetreuer und Gastkritiker an der TU Darmstadt. Seit 2006 Assistent am Lehrstuhl für Holzkonstruktionen IBOIS der EPF Lausanne, wo er momentan seine Dissertation zum Abschluss bringt.

Workshop

Fabricating Form

Das Fügen von Elementen zu einem Ganzen ist eine Notwendigkeit bei der Realisierung von Gebäuden, hat darüber hinaus aber auch generatives Potential. Der Workshop “Fabricating Form” untersucht in diesem Zusammenhang die Frage, inwieweit aus dem Zusammenspiel von Fügungsprozessen und Elementeigenschaften architektonische Form entstehen kann.

Ausgehend von streifenförmigen, elastisch verformbaren Elementen werden auf empirische Art und Weise neuartige Formen der Fügung entwickelt, welche die spezifischen Eigenschaften dieser Elemente berücksichtigen, beziehungsweise durch diese erst ermöglicht werden. Ausgangspunkt sind textile Prinzipen und Techniken, die dann im Verlauf des Workshops weiterentwickelt und modifiziert werden.

Lecture

Timberfabric – Textile Assembly Principles and Wood Construction

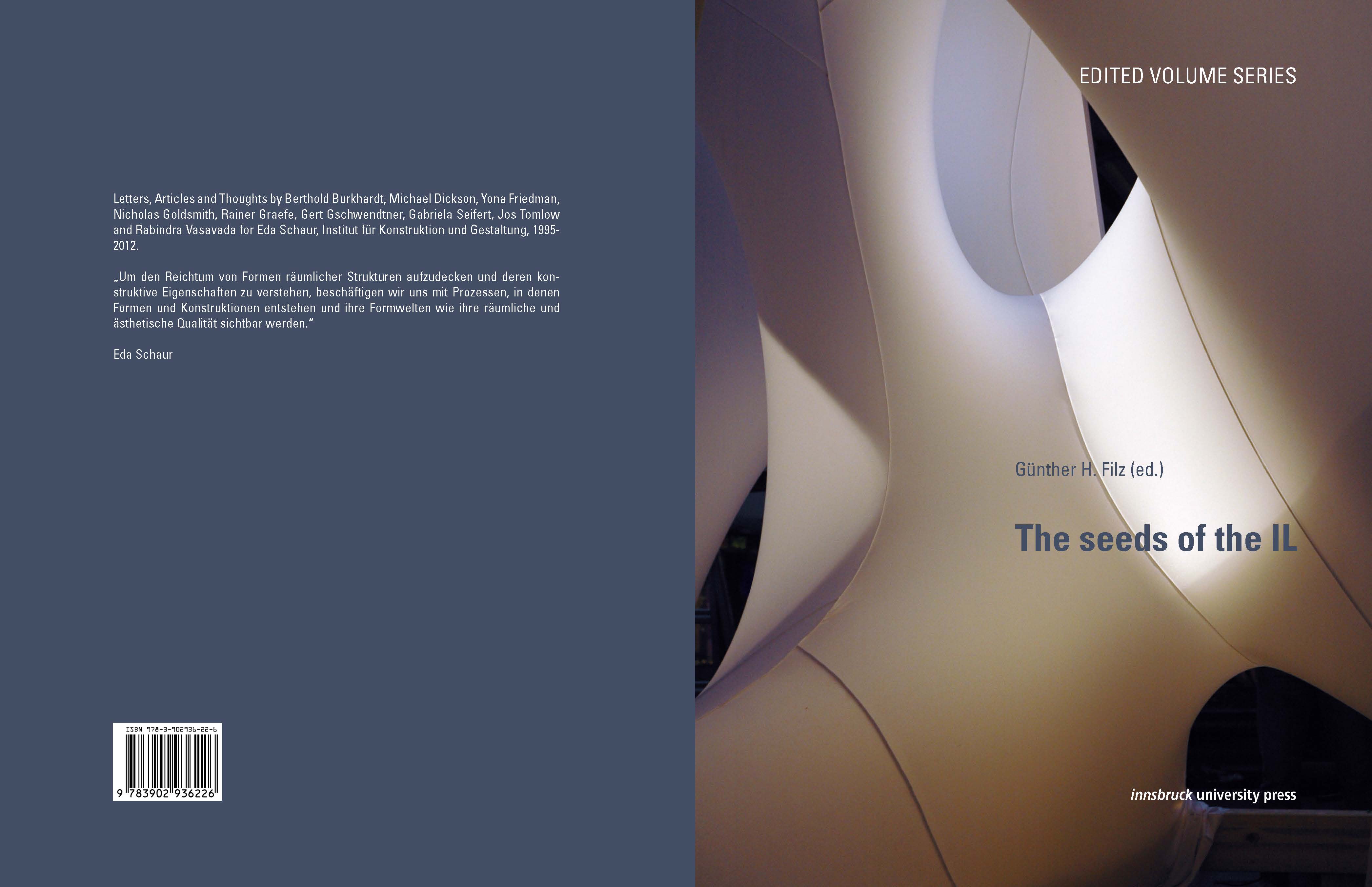

The research work Timberfabric explores the interplay between assembly processes and the properties of the involved components and the potential of this interplay as generative factor in architectural and structural design. More specifically, it examines how principles of textile assembly techniques, in combination with elastically deformable timber elements, can be employed for the development of an innovative unit based construction system.

The research pursues an empirical approach and is organized in three parts. In the first part, the Timberfabric Module is determined as basic unit for the modular system that is the goal to develop. The second part examines the properties of this module and the implications of producing it in large size. The third part systematically explores different possibilities of combining multiple modules into more complex structures and how the connectivity between their components can be established and optimized. The production of physical models and prototypes plays a pivotal role throughout the process. Physical modeling allows for a direct experience of the material’s elastic deformability and the impact of the proportions of the basic elements. It further contributes to a general understanding of the geometric foundations of the developed structures as well as their mechanical properties.

The resulting models and prototypes are examined with regard to a series of select evaluation parameters. Amongst others, the overall impact of transferring textile assembly principles to the domain of timber construction is discussed. Analogies and differences between the developed and actual textile structures are identified. It is shown that the interplay between material properties and assembly techniques does not only generate a specific architectural form of expression, but also contributes to the spatial and structural qualities of buildings. The derived findings provide the basis for a modular construction system for self-supporting building envelopes.